1. Definition and core concepts of CNC machiningCNC machining, also known as Computerized Numerical Control, refers to computer digital control machining. It is a technology that uses CNC machine tools to automate the processing of metals and other materials. The core of CNC machining lies in using digital information to control the motion and machining process of machine tools, thereby achieving high-precision and high-efficiency part manufacturing.

2. Working principle of CNC machiningThe working principle of CNC machining mainly includes the following steps:

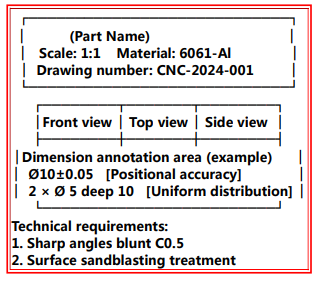

Programming: Technicians write CNC programs (usually G-code) based on the machining requirements of the parts, describing the tool's motion trajectory, machining parameters (such as spindle speed, feed rate, etc.), and auxiliary functions (such as tool changing, coolant switch, etc.).

Input and decoding: The pre written CNC program is input into the CNC system, which decodes the program and converts it into instructions that can be executed by the machine tool.

Execution of machining: CNC machine tools automatically control the relative motion of cutting tools and workpieces according to instructions to complete machining operations.

3. Characteristics and advantages of CNC machiningCNC machining has the following significant characteristics:

High precision and high stability: Through digital control, CNC machining can achieve micrometer level or even higher precision machining, and the machining quality is stable.

High efficiency: CNC machine tools can automatically complete multiple processes, reduce manual intervention, and significantly improve production efficiency.

High flexibility: By modifying the CNC program, CNC machine tools can quickly adapt to the processing needs of different parts, suitable for small batch and multi variety production modes.

4. Application areas of CNC machiningCNC machining is widely used in fields such as mechanical manufacturing, mold processing, aerospace, and automotive manufacturing. Especially in mold processing, CNC technology can efficiently solve the processing problems of complex and precision parts, becoming an indispensable technical means in modern manufacturing industry.

5. Development Trends of CNC MachiningWith the advancement of information technology and automation technology, CNC machining is developing towards high-speed, high-precision, intelligent, and multifunctional directions. In the future, CNC technology will further promote the automation and intelligent upgrading of the manufacturing industry.

From the above analysis, it can be seen that CNC machining is an advanced manufacturing technology that integrates digitization, automation, and high precision, playing an important role in modern industry.

|